Trusted Experts in High Pressure Coolant Systems and Accessories

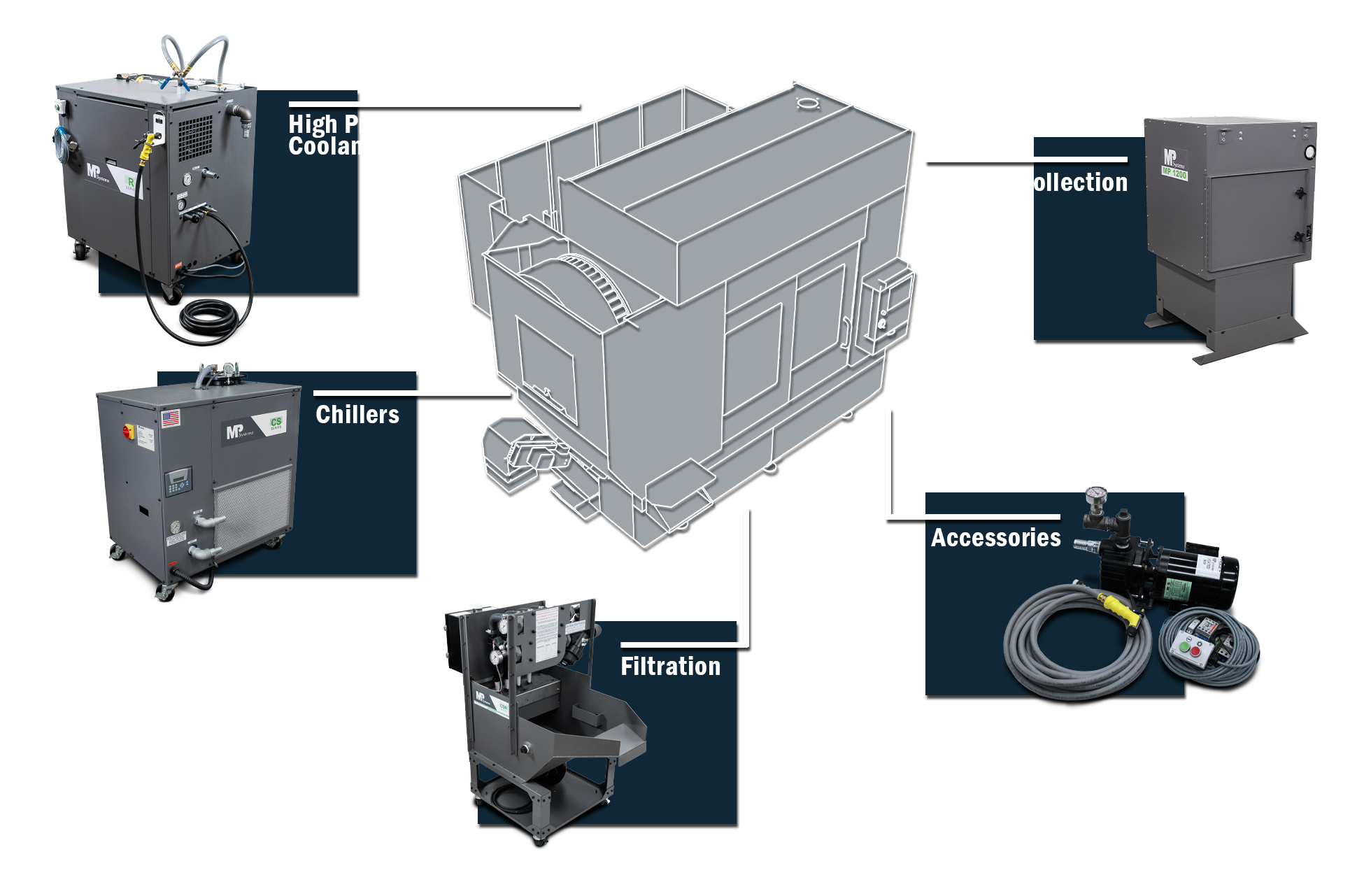

MP Systems designs and manufactures rugged, dependable high pressure coolant systems, chillers, coolant filtration systems, and accessories for the machine tool world. Because we have a comprehensive understanding of the stress points in machining, our products minimize machine tool downtime and maximize tool life.

For live technical support and service, please call us at 877.689.1860.