The Most Effective Coolant Filtration Solutions on the Market!

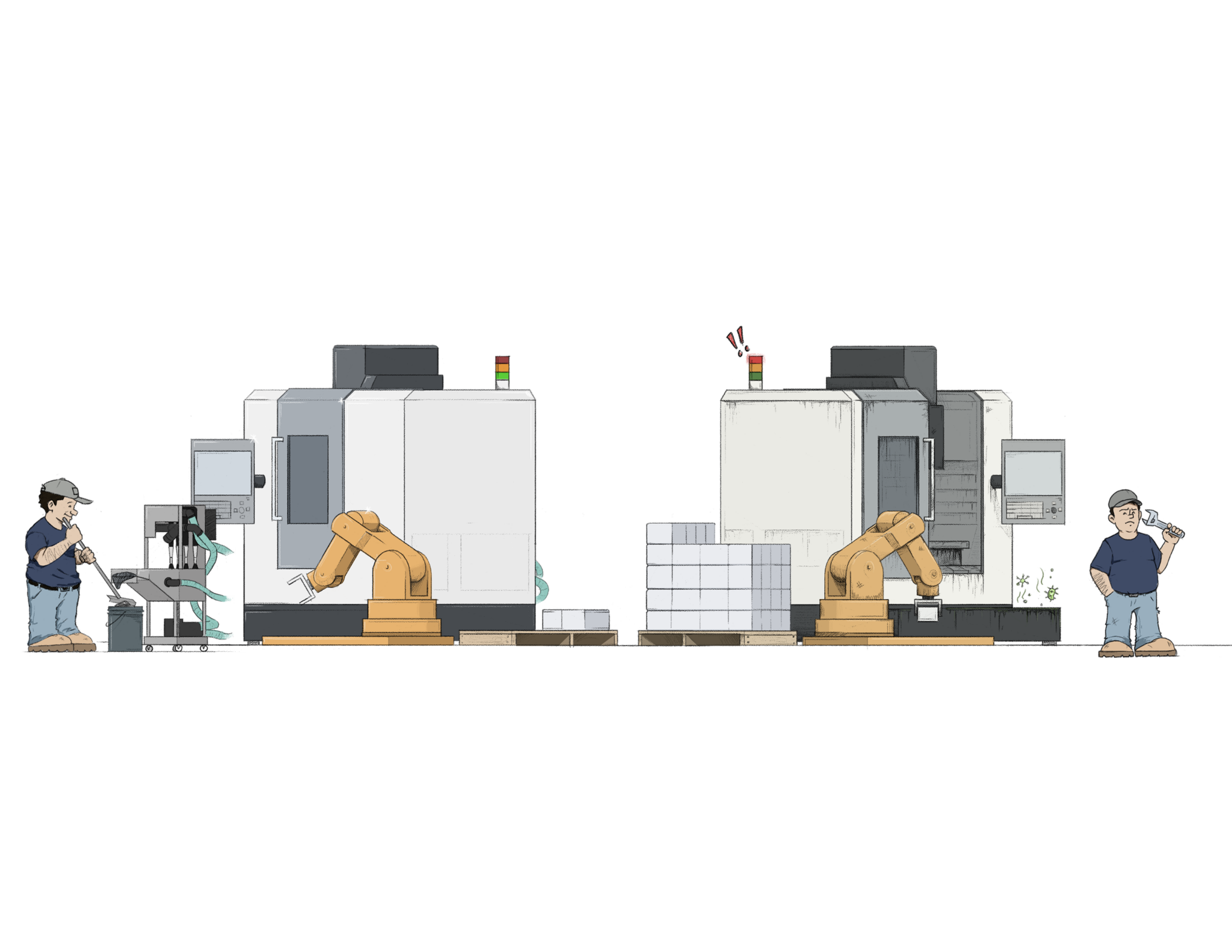

Protect your machines from pre-mature wear.

Coolant filtration is an often overlooked issue in the machine tool industry because of the lack of effective solutions on the market - until now.

MP Systems offers filtration solutions for large fines all the way down to tiny hard sharp debris. Our units operate separately of the high pressure systems allowing for uninterrupted machining on almost any application.

Effective coolant filtration will keep your machine tools clean and running for longer with fewer shutdowns due to unexpected repairs and service. MP's coolant filtration systems are designed to save money and keep parts moving out of your shop!

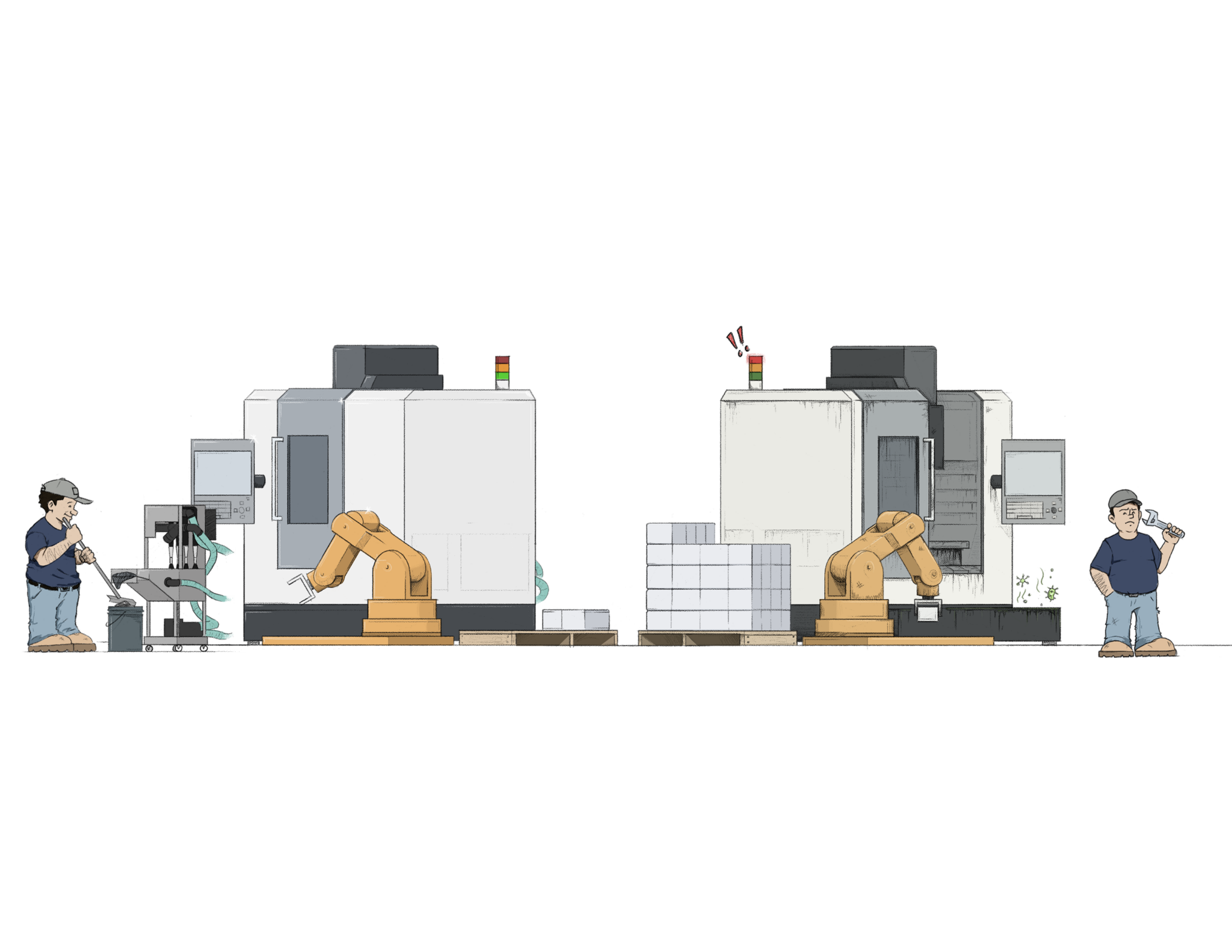

Protect your machines from pre-mature wear.

Coolant filtration is an often overlooked issue in the machine tool industry because of the lack of effective solutions on the market - until now.

MP Systems offers filtration solutions for large fines all the way down to tiny hard sharp debris. Our units operate separately of the high pressure systems allowing for uninterrupted machining on almost any application.

Effective coolant filtration will keep your machine tools clean and running for longer with fewer shutdowns due to unexpected repairs and service. MP's coolant filtration systems are designed to save money and keep parts moving out of your shop!

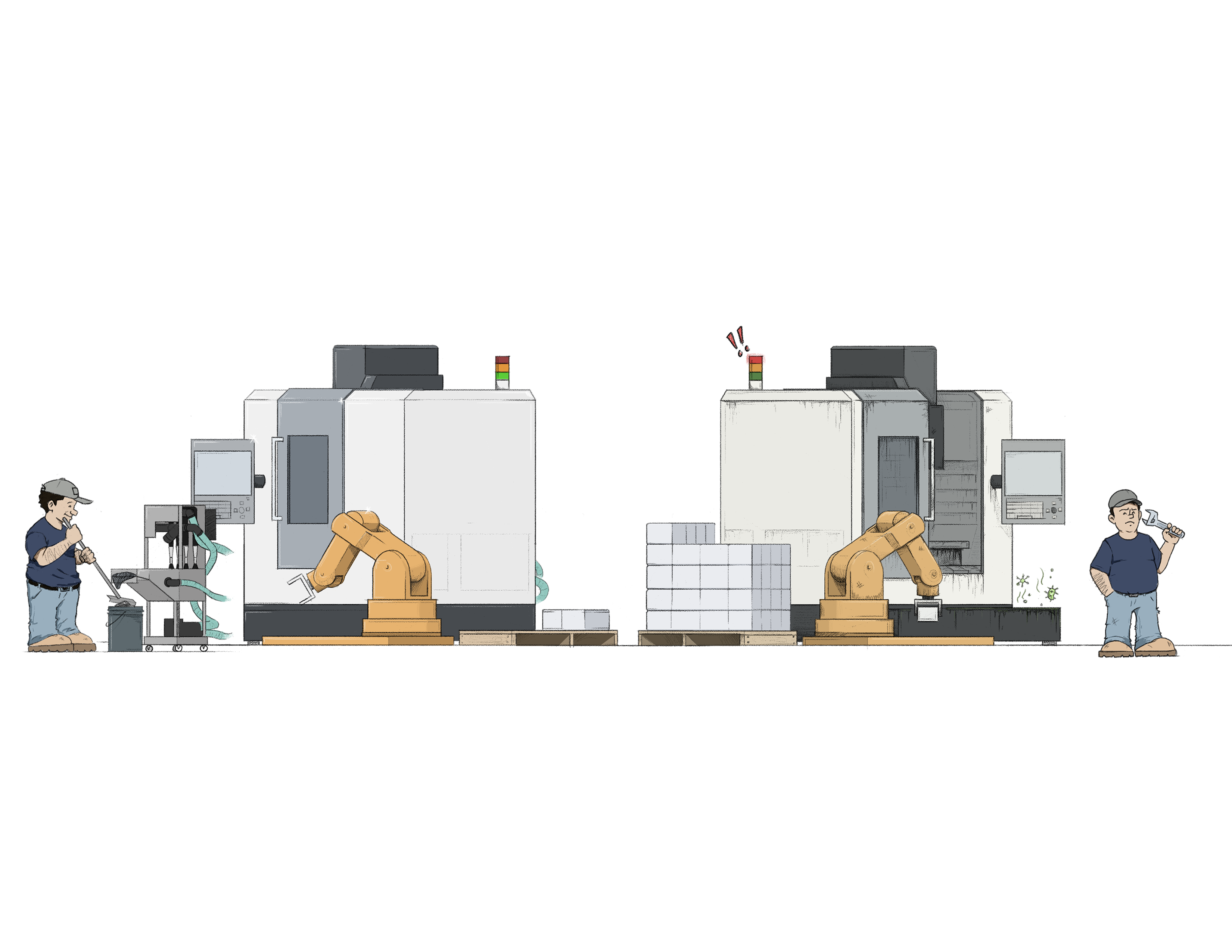

Protect your machines from pre-mature wear.

Coolant filtration is an often overlooked issue in the machine tool industry because of the lack of effective solutions on the market - until now.

MP Systems offers filtration solutions for large fines all the way down to tiny hard sharp debris. Our units operate separately of the high pressure systems allowing for uninterrupted machining on almost any application.

Effective coolant filtration will keep your machine tools clean and running for longer with fewer shutdowns due to unexpected repairs and service. MP's coolant filtration systems are designed to save money and keep parts moving out of your shop!

FILTRATION SOLUTIONS

Cyclonic Debris Removal (CDR)

Prevents tiny hard sharps from contaminating coolant and wearing machines cutting high volumes of hot finished parts without the need of filter media. The ideal solution for automated/unattended machining.

Purge Filtration System

Keep your tank clear of larger fines and debris using high capacity, full flow filtration with the Purge. Works with a variety of materials. Designed for quick, ergonomic filter change outs without shutting down production.

What are some common pain points caused by dirty coolant?

- Machine tools deterioting faster than normal

- Worn components (i.e. waycovers, liner guides, ballscrews etc.)

- Unexpected shutdowns

- Lack of precision/inconsistent output

- Little confidence in unattended/automated machining

- Frequent tank cleanouts

- Smelly, bacteria-ridden coolant

- Blinded-off filterbags

- Chip dams at filter screens

- Coolant starvation of flood & high pressure pumps

- Short coolant life

- Poor workpiece finish

- Short tool life

What are some common pain points caused by dirty coolant?

- Machine tools deterioting faster than normal

- Worn components (i.e. waycovers, liner guides, ballscrews etc.)

- Unexpected shutdowns

- Lack of precision/inconsistent output

- Little confidence in unattended/automated machining

- Frequent tank cleanouts

- Smelly, bacteria-ridden coolant

- Blinded-off filterbags

- Chip dams at filter screens

- Coolant starvation of flood & high pressure pumps

- Short coolant life

- Poor workpiece finish

- Short tool life

The MP Promise.

The team at MP Systems have worked hard to engineer filtration solutions that eliminate the problem at the source. The filtration options we produce have been engineered to keep up with the hardest working shops. Our systems are rated for continuous duty and come with a 2 year parts warranty.

All MP Systems products are backed by our Live Engineer Support line which connects you with a real engineer within minutes to troubleshoot and resolve any issues that may arise so ensure as little downtime as possible. We are dedicated to keeping your machines up and running.

The CDR utilizes four carefully engineered hydrocylones to separate tiny harmful particles from a machine's coolant, meaning no disposable filter media is required. The CDR is a virtually maintenance free system, ideal for automation/unattended machining. This system efficiently filters down to roughly 3 micron for heavier materials and water-based coolant.

The Purge is an expertly designed bag filter system that uses pressurized vessels to effectively capture larger fines and chips that would otherwise contaminate a machine's coolant tank. This system can greatly extend tank cleanouts and prevent unexpected shutdowns. The Purge filters both water and oil-based coolants and can be used with a variety of materials.