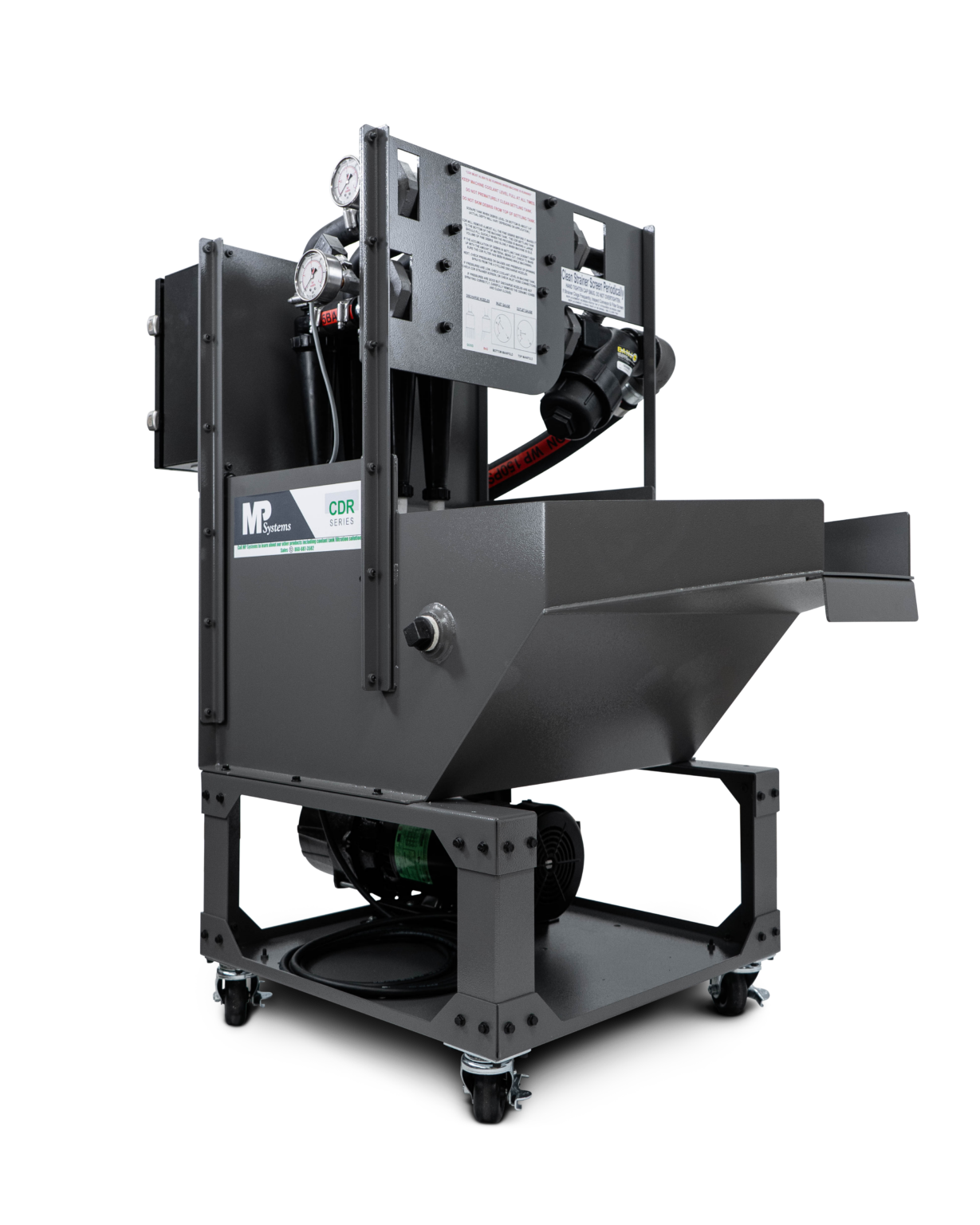

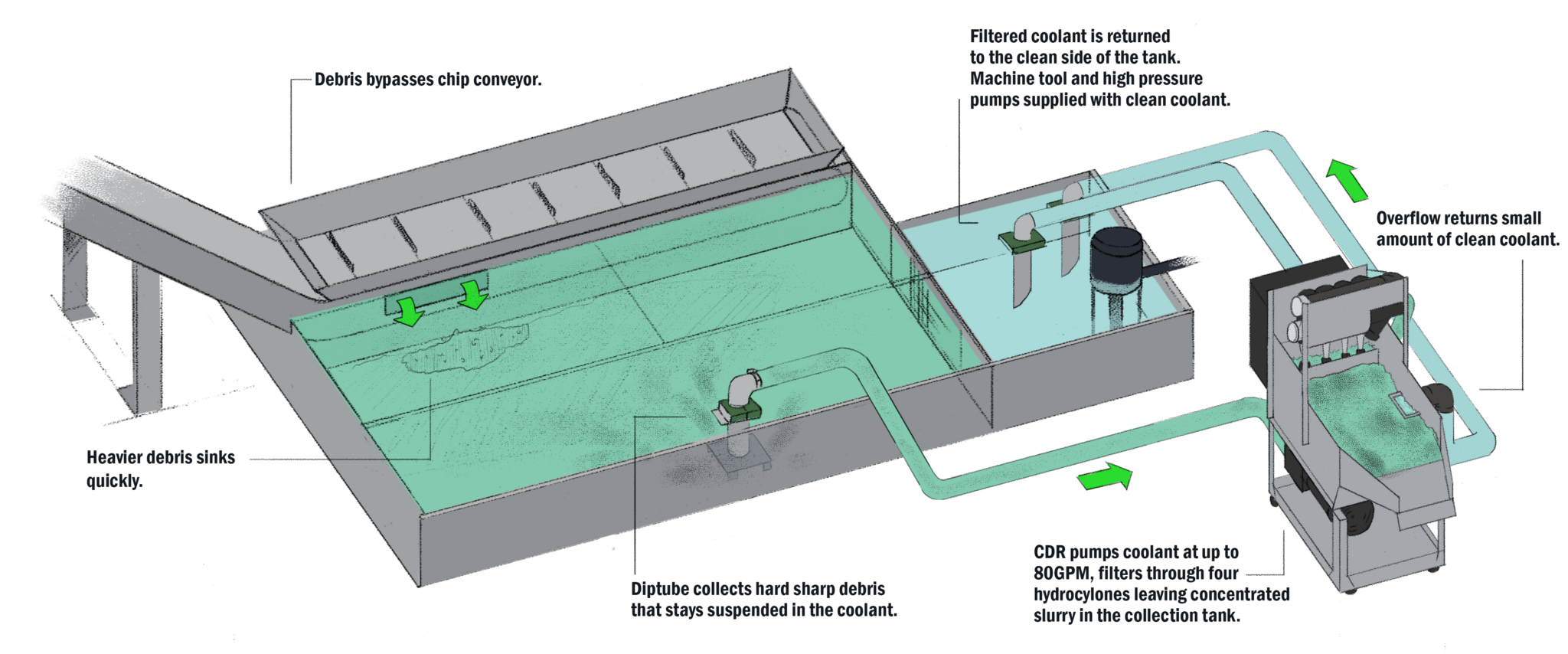

HOW CDR WORKS

The CDR utilizes four expertly engineered hydrocylcones that separate the hard sharp particles that typically stay suspended in a machine's coolant. The CDR's 3HP pump produces up to 80GPM flow rate in order to quickly capture harmful debris before it is recirculated through the machine.

The debris is separated out, and lands in the settling tank where it can easily be scraped out. The clean coolant returns to the machine tool tank, supplying your pumps with fresh coolant and protecting your machine from wear.

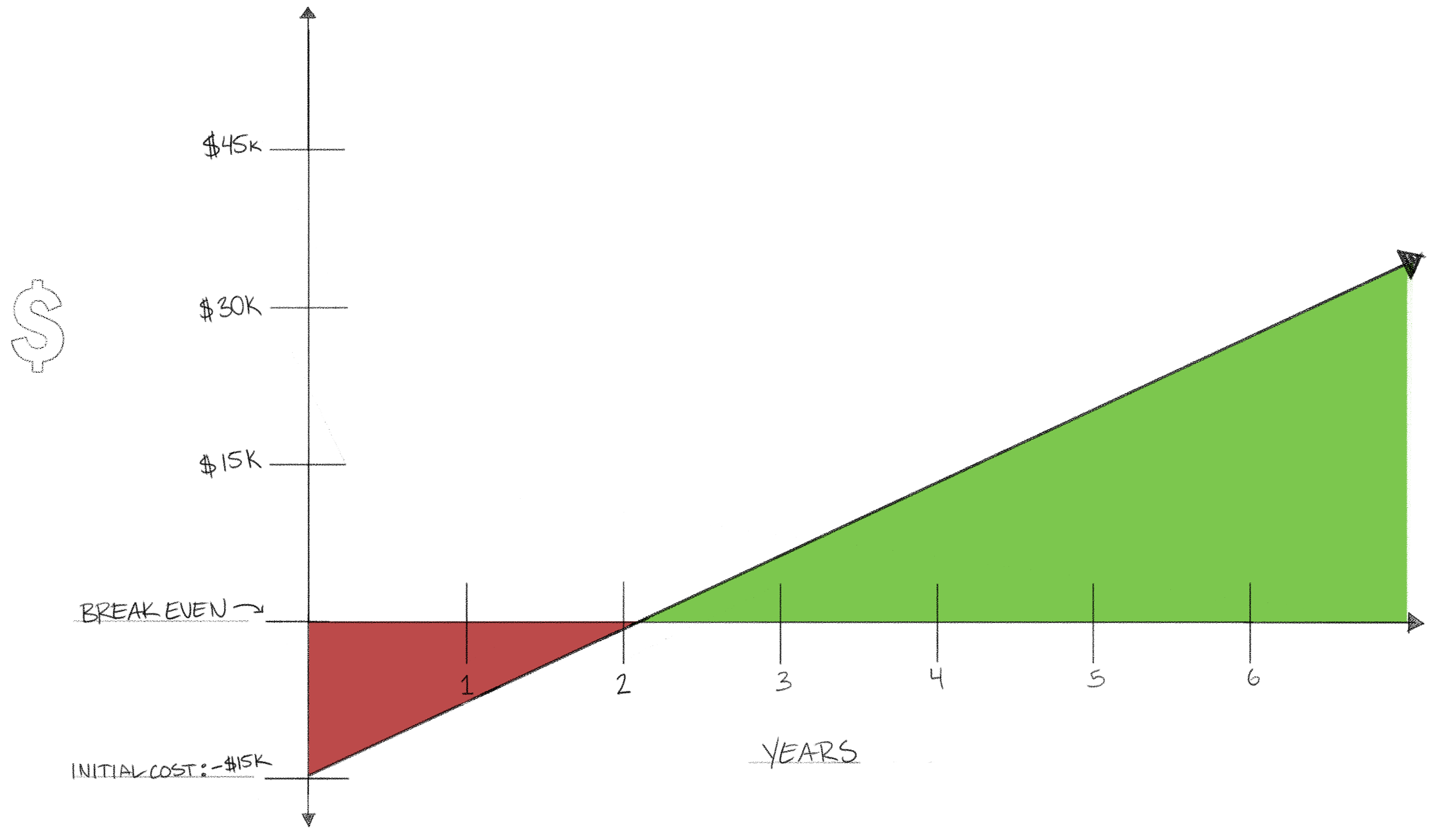

RETURN ON INVESTMENT

Averaging over a CDR’s life, it will typically pay for itself in 2 years.

- COST OF REPLACING SET OF WAYCOVERS: $5,000-$20,000

- COST OF REPLACING BALL SCREW/LINEAR GUIDES: Starting at $10,000+ per axis

- TOOL HOLDERS: $50-$100 each

- CHUCK: $4,000-$20,000

- MACHINES RUN IN SEVERE ENVIRONMENTS TYPICALLY NEED A MAJOR REBUILD IN 5-10 YEARS: $150,000

- COOLANT COST IN & OUT: $450-$1,050 per tank cleanout

- LABOR COST: $100-$640 per tank cleanout

Damage and maintenance costs increase over time, but wear may not be noticeable until it’s too late.

CUSTOMER TESTIMONIAL

Working In Tandem: A CDR Success Story

This shop utilizes automated machining centers that run multiple shifts cutting cast iron parts - in turn creating large amounts of dust that combines with their coolant, creating a nasty sludge

We provided them with a solution: the CDR. They now run the Cyclonic Debris Removal on over 40 machines, preventing unexpected shutdowns caused by clogged coolant lines, starved feed pumps and worn out components. We also decreased the frequency of filter bag changes in our high pressure pump.

"In my eyes, every machine cutting these parts needs a CDR." - Shop Manager

- Up to 80 GPM flow rate

- Filtration down to 3 micron

- Cleanable Pre-filter

- No Disposable Filter Media

- Low maintenance

- 2 year parts warranty

- Inlet/Outlet Pressure Gauges

- Easy Install Kit

- PLC display

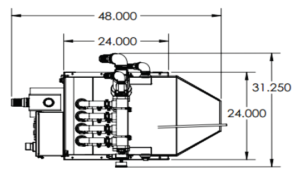

Note: All units are in inches.